Finetuning & Service

The complete PCAP solution from HY-LINE

The heart of the touchscreen system is the touchscreen controller. It evaluates the touch events by sequentially scanning the rows and columns. The basic functions are: Recognition of a touch event ("touch"), disappearance of a touch event ("release") and the recognition of gestures ("swipe", "zoom", "pinch"). Depending on the settings, several events can be evaluated simultaneously ("multi finger" touch and gestures). The software running on the touch controller covers all these functions. The basic functions can be parameterized within wide limits to adapt the function of the touch screen to the desired user interface and electrical environment. This is also called "fine tuning", where over 50 parameters are set in the firmware.

Since the PCAP principle is based on changing minute capacitances, all influences that affect the electrical field emitted by the sensor must be taken into account or eliminated, e.g.

- Material and thickness of the front panel

- Interference fields from display, switching power supplies and power supply

- Interference fields introduced during the EMC test

Once these influences have been eliminated, the touch controller is set to the desired operating mode:

- Number of touches to be recognized simultaneously (multiple fingers)

- Recognition of gestures

- Sensitivity, e.g. for fingers in gloves

- Thickness of the cover glass

- Suppression of unwanted events such as applied palms of the hand

- More difficult conditions due to foreign objects on the surface such as water drops, flowing or standing water or other liquids

In addition, the controller firmware evaluates the events and checks them for plausibility. If necessary, the operating mode is changed to effectively suppress interference.

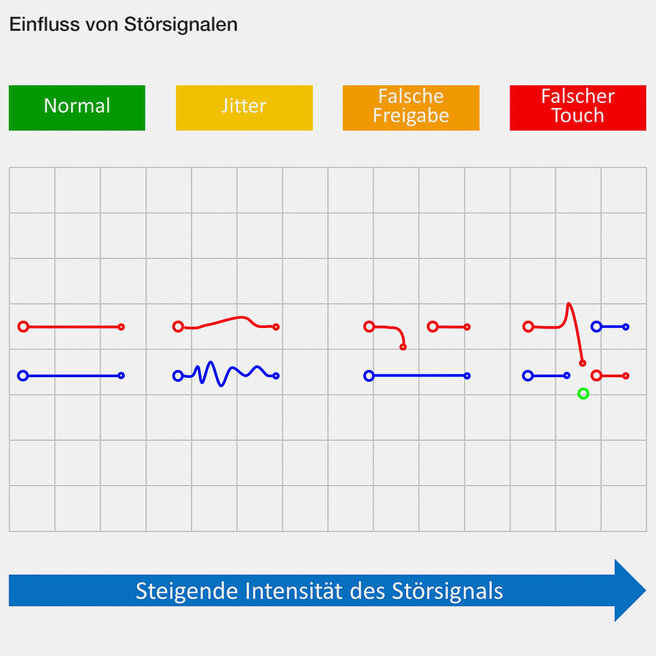

The figure shows the effects that interference signals can have on a touchscreen that is not optimally tuned. Large circles indicate a touch event, small circles mark release. Lines show the path of continuous touch.

Two parallel lines were drawn on the touch sensor. From left to right are shown:

- Without interfering signal: touching and releasing the touchscreen work properly, the coordinates of the touch events are detected correctly.

- With increasing intensity, the localization of the touch events becomes more difficult: The recognized position partly deviates significantly from the real one. Touch and release are detected perfectly.

- With further increasing interference signal, there are stronger deviations from the correct position. The simultaneous presence of several touch events is not reliably detected. Despite contact between finger and touchscreen, a release is detected and reported to the system.

- With the strongest interference signal, the touchscreen's function is practically completely disrupted: Touch and release are no longer reliably detected, "ghost" events (green) occur without touch, and the assignment of the fingers to the coordinates is no longer correct (red and blue alternate).

Whitepaper: Successfully Integrate PCAP Touchscreen

Valuable knowledge for system integrators

For more information about integrating a PCAP touch system into your device, please refer to our whitepaper. The task of this whitepaper is to eliminate possible sources of problems when using a PCAP touch design, to explain different installation variants and to select the right components. In this completely revised version, we have incorporated experience gained over the past few years by our experts in the fields of technology, design and sales.

Q&A

HY-LINE engineers tune each system to the desired functions and the existing environmental conditions. For this purpose, you send a device from near-series production to us. The time required depends on the effort and will be coordinated with you.

No, a one-time calibration/fine tuning on the final prototype is sufficient.

No, a one-time calibration/fine tuning on the final prototype is sufficient.

For each display a separate firmware for the touch controller has to be created and assigned to the display in the final assembly of the device.

Basically yes, if the system's reserves (signal-to-noise ratio, thickness of the glass, other environmental conditions) allow it. In this case, a new firmware must be installed in each controller. Please contact us for this.

Under certain conditions, we can also offer "remote tuning".

Consulting and contact

Your wishlist is empty