Touch-Displays

HMI front unit consisting of display and touch

What would a display be without a touchscreen? Driven by the consumer world, in which smartphones are omnipresent, many displays are not only used for displaying information, but also for entering data. Here, too, there are various technologies, each of which has its justification, be it conventional resistive, innovative infrared or particularly versatile PCAP (projected capacitive).

Unlike in the office, displays in industrial applications are not used without a cover lens to protect the sensitive polarizing filter from damage and contamination. This glass, also known as a “cover lens”, significantly expands the range of applications for displays: it serves as a carrier for PCAP touchscreens, which are often designed as a film, because a good optical and electrically stable connection can be achieved by lamination. The glass can be mechanically processed in a variety of ways to fit the application perfectly.

At the same time, the cover serves as a carrier for EMC films against irradiation and radiated interference, can be designed as a heating element to prevent fogging and, especially outdoors, keep harmful infrared (heat) and ultraviolet radiation away from the display.

We advise you on the selection of the right technologies for the display and touchscreen and work with you to develop the complete HMI front unit for your device, functional and with an attractive design.

Individual fine-tuning of the touchscreen means that operation with several fingers, gestures, with gloves and even under the influence of moisture is no problem!

If you are looking for a securely functioning system with display and touchscreen, you have come to the right place! We supply the complete unit, consisting of a display (from 2.4“ to 32”), a touchscreen (usually in PCAP technology) and a cover lens according to your specifications or in a jointly developed design. There are many degrees of freedom:

- Diagonal from 2.4“ to 32”, resolution up to 4k, brightness from 250 to over 1,000 cd/m², interfaces RGB parallel, SPI, LVDS, MIPI, VByOne

- Connection via standard connector or customer-specific flex foil

- Special functions such as integrated backlight driver, brightness sensor, EEPROM for identification

- Touch sensor with multi-finger, gesture control, glove operation precisely tailored to the application

- Printed cover glass from 1.1mm to 8mm, also in laminate, tempered if required (“Gorilla®”, “Xensation®”, ESG (toughened safety glass) and others)

- Contour and surface of the cover glass customized

- Refinement, e.g. through optical bonding

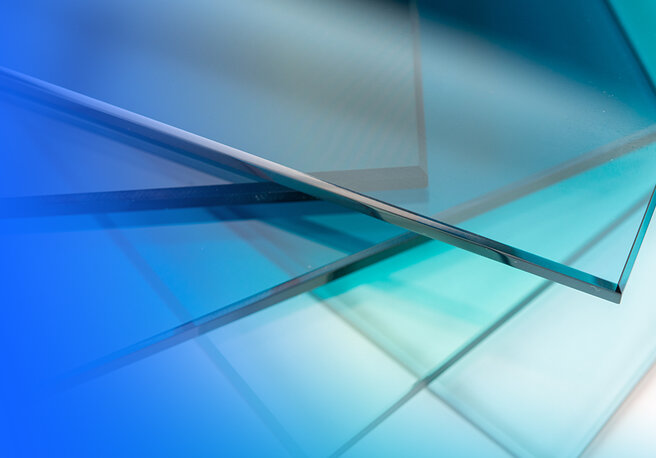

Cover Glass

Protective glass for touchscreens and displays

The cover glass, also known as the front glass or cover lens, is the component of the display system with which a user interacts through direct contact.

It has a variety of tasks:

- Protecting the display from external influences such as dust, scratches, vandalism, UV and IR radiation

- Optimization of readability through a low-reflection surface

- Design element of the device through printing in different colors

- Part of the front of the device thanks to special design

- Carrier of the PCAP sensor for touch terminals

Since the introduction of PCAP technology, the cover glass has been of particular importance, as this touch technology is the first to separate function (touch sensor) from design (cover glass).

Designed as safety glass or tempered glass, it resists attacks on the surface or is destroyed in a defined manner (breaking into small, blunt pieces).

Surface and processing options

The surface is part of the look of the overall system and is coated as anti-glare or anti-reflective depending on the requirements and environment. Other functions such as anti-fingerprint or a coating to kill germs are also possible. For special applications in medical and food technology, a plastic replaces the glass material.

As the cover glass is larger than the outer dimensions of the display, the edge can be graphically designed. This starts with a simple black print and extends to icons and company logos. Sensors, e.g. for brightness and presence, can simply be hidden behind the cover glass. Different processes (screen printing, ceramic printing, digital printing) each have advantages and disadvantages and must be selected depending on the application. The printing is always done on the back of the cover glass, so that wear and tear due to abrasion is not relevant.

The processing options for the cover glass also allow non-rectangular contours and openings, e.g. for an emergency stop button.

If a touch sensor made of foil is used, it is glued to the back of the cover glass. The entire structure is in turn bonded to the display behind it. Methods for this are "tape bonding", in which double-sided adhesive tape is used, and "optical bonding", which is described in more detail below.

Refinement technologies

- Mechanical processing: smoothing and profiling of edges, rounding of corners, emergency stop switch, viewing window, slot for ticket issuance.

- Etching: Antireflection coating, image sharpness, surface robustness, finger guide

- Printing: privacy screen, message text, label, capacitive key display

- Coating: Anti-reflective, anti-static, electromagnetic shielding, anti-fingerprinting

- Bending: Fitting to housing shape

- Hardening/Pre-stressing: Vandalism protection, increase fracture resistance, color resistance (ceramic printing)

- Laminating: Splinter protection, use of special films, increase in material strength (vandalism).

Example: Curved cover glass

The customer wanted a curved display for a design-driven application. The challenges were:

- The device must have a touchscreen for operation

- Displays are normally flat

- The parallax should be minimal, the display should be readable from all sides and the touchscreen should be operable from all sides

We accepted the challenge and laminated the foil touch sensor into the curved glass. We did not bend the display. For the resulting difference in thickness between the display and sensor/cover glass, we found a material that fills the volume and hardens perfectly even with varying thickness. At the same time, it offers excellent optical properties that minimize the unavoidable parallax when viewed at an angle.

The customer used the possibilities of glass processing here and had the corners and edges of the display rounded to match the design. The white print allows the display to blend in perfectly with the device design, especially when active, while the bonding gives it a deep black appearance when switched off.

What types of curved glass do we have?

- Convex bending

- Concave bending

- Bending in several planes or axes

In addition to the challenge of touch adjustment, possible optical parallax errors must also be kept in mind. Optical bonding significantly reduces these.

Types of glass

- Anti-Glare Glass (AG): matched to the display, prevents sparkling; anti-reflective surface; simplifies finger guidance

- Anti-reflective glass (AR): optically anti-reflective for optimal reading in sunlight; Anti Finger Print coating for touch applications

- Laminated safety glass (VSG): depending on IK class from wafer-thin to extremely thick; protects against shattering and vandalism

- EMV- and UV-shielding glasses: Privacy discretion with lateral view

- Antibacterial glass (for medical technology)

In many cases, the individual features can also be combined with each other, and customized cuts in all possible sizes are possible.

Product features

- 100% dust-tight bonding, no gaps due to continuous circumferential adhesive bead. Protective glass/touch sensor can generally be replaced during servicing without damaging the TFT.

- Waterproof bonding possible (e.g. protective glass can also be bonded in customer-specific housing)

- High temperature resistance - no adhesion problems at extreme temperatures

- Better/professional appearance than with conventional adhesive tape mounting

- More exact positioning of the sensor/protective glass compared to adhesive tape mounting

- No evaporation of plasticizers or corrosive gases

- No dimensional change and thus no sealing problems with respect to the bezel when the glass is pressed strongly, since the adhesive is significantly more dimensionally stable than the double-sided foam tape

- Small distance TFT/touch/glass, thus less parallax effects and space saving in the construction depth

- If required, other bonding can also be carried out, e.g. glasses/sensors directly in front panels etc.

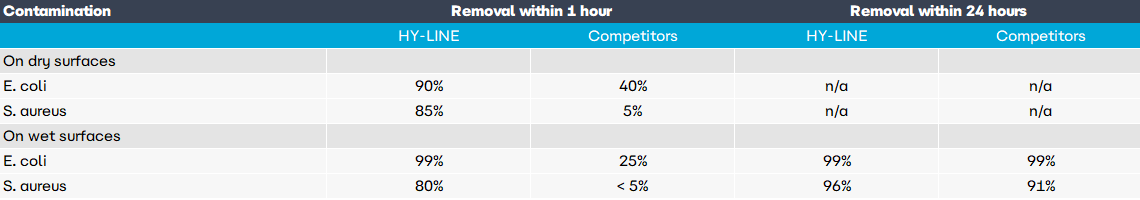

Antibacterial glass

Especially during the winter months and in the current situation, protection against bacteria on touchscreens is essential. With the Antibacterial Glasses we have the ideal solution for medical monitors or terminals in the public sector such as ticket machines or elevator controls.

Our Antibacterial Glass makes colonization by bacteria much more difficult. In the tests carried out so far, none of the bacterial species applied on a trial basis were able to settle on the glass.

Features

- Coating can be applied to any type of glass (AR, AG, Clear)

- Easy to clean

- Extremely high transparency

- Protection of the underlying units

- Minimization of colonization by bacteria

- Minimization of contamination between cleaning cycles

- Resistant to chemical and mechanical influences, as well as UV radiation

- Resistant to the most commonly used disinfectants based on alcohols, aldehydes, hydrogen peroxide and chlorine

Fields of application

- Medical monitors

- Ticket and cash machines

- Elevator panels

- Light switches

- Control elements

- Areas with special hygiene requirements, such as hospitals, laboratories, canteens, bathrooms, wellness areas, swimming pools, toilets, etc.

Consulting and contact

Your wishlist is empty