Optical Bonding

For ideal readability, longer life and more cost savings

"Optical bonding" means "transparent liquid bonding". It describes an adhesive technique used to bond displays, touch or front glasses together with a high optical quality. Optical bonding helps an industrial touch display become more stable, protects against moisture and dust, and improves the optical properties. The unit thus becomes significantly more durable and of higher quality.

Due to significant improvements in automation and production, the advance in the industrial sector is unstoppable, e.g. in demanding medical and outdoor applications.

HY-LINE advises and selects the right bonding process for your application to deliver the optimal end product adapted to your needs.

Advantages for the user and the system integrator

The end user - at the ticket machine, at the point-of-sale terminal, on the construction machine - expects a display that is readable under all lighting conditions.

The system integrator can improve readability by using a material with better optical properties than air - optical bonding. The increased cost of the process is more than compensated for by the resulting benefits:

- Improved display quality

Of course, the technical arguments still apply: the display remains eminently readable even in difficult lighting situations, the device acquires a more valuable impression and gains through increased user-friendliness.

- Design claim

When the active display is brilliant, the display surface blends in with the surrounding frame of the cover glass instead of reflecting the surroundings when it is switched off. The surface appears homogeneous and noble.

- Mechanics

The mechanical stability is increased by the bonding material; a thinner and thus lighter cover glass can be used. This allows the display to withstand harsh or vandalism-prone environments. With a plastic cover glass, the requirements for shatter protection, such as those in the food industry and medicine, are met.

- Longer life, less energy consumption

Better contrast allows lower brightness to achieve the same ratios as the non-bonded display. The use of special high-brightness displays can be dispensed with.

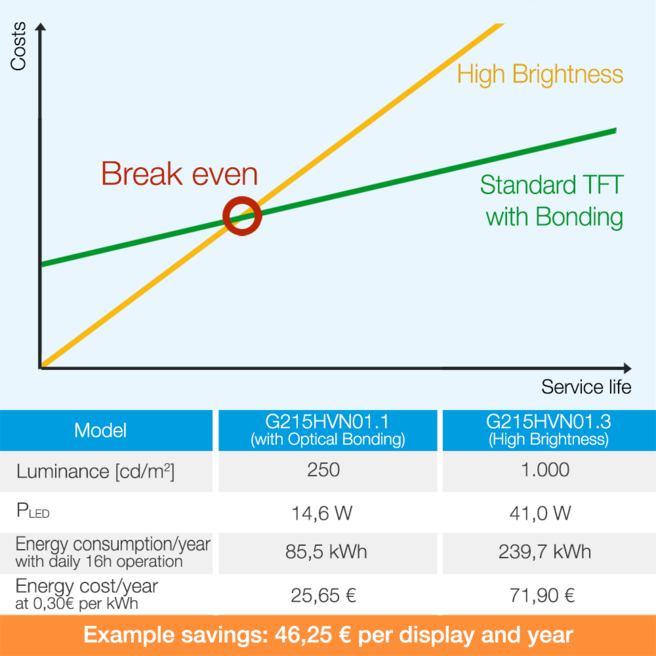

Optical Bonding instead of High Brightness-Display?

If you opt for optical bonding, the display becomes easier to read. You can therefore reduce the display's brightness. This has positive side effects:

- Energy savings

A standard display needs less energy for the LED backlight to be just as readable. The graph shows that the higher initial costs incurred with optical bonding pay for themselves in a short time. If many displays are installed, e.g. in supermarkets, this quickly adds up to a five- to six-figure sum per year. - Longer service life

If the LED backlight is operated at a lower brightness than the maximum specified in the datasheet, the service life of the display and thus of the overall product is extended. The display will not need to be replaced as often, if at all, during the life of the unit due to diminishing brightness. - Extending battery life

The lower power consumption allows the device to run longer with the same battery capacity. Alternatively, a smaller battery can be used, saving further costs. - Lower costs

A high-brightness variant is not available for every display model. These often cost a significant premium because more material has to be used, increased effort is required for heat dissipation and an attractive price cannot be offered due to the lower quantities.

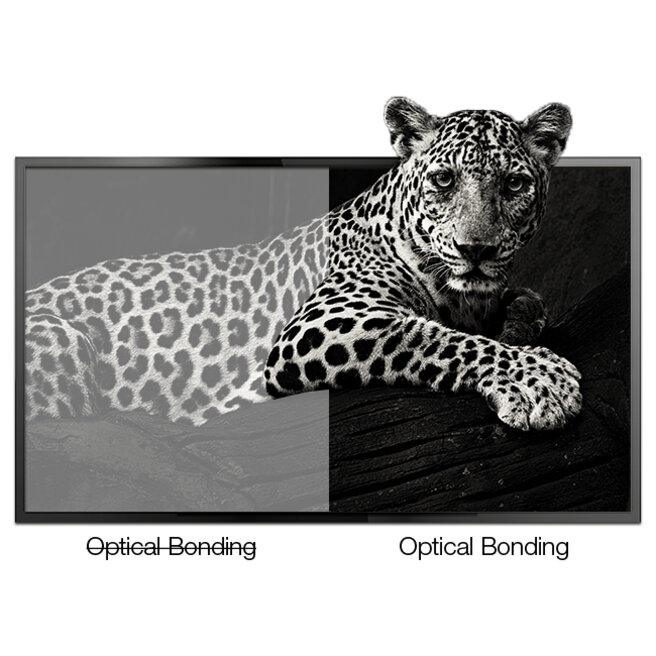

Improved readability due to optical bonding

When light passes from one medium to another with a different refractive index, most of it is refracted along the optical axis and some of it is reflected. The proportions depend on the ratio of the refractive index. In the case of a composite of cover glass, touch sensor and display, light from the environment, i.e. from the sun or artificial light sources, is reflected several times during the transition, which leads to a reduction in contrast.

Neglecting other components such as the surface finish of the cover glass or the internal structure of the touch sensor results in the ratios shown in the graphic below. On the left, light is first reflected from the surface of the cover glass, then from the underside of the sensor when it passes into the air between the sensor and the displays, and finally when it passes into the surface of the display. At each interface, about 5% is lost by reflection, so that a total of 15% of the light hitting the cover glass is reflected, degrading the contrast of the display.

If the air space between the sensor and the display is filled with a material (see graphic on the right) that has a refractive index similar to that of glass, only a small amount of reflection occurs there. The total reflection is thus reduced to 5%, which can be pushed to below 1% by an anti-glare or anti-reflective coating. However, the light emitted by the display is also reflected and contributes to a deterioration of the contrast with a reduced brightness due to the loss through reflection.

Whitepaper

The white paper highlights topics such as components, application areas, advantages and challenges of optical bonding and explains in detail the individual bonding processes for display and touch. (This Whitepaper is in german.)

Consulting and contact

Your wishlist is empty