Your wishlist is empty

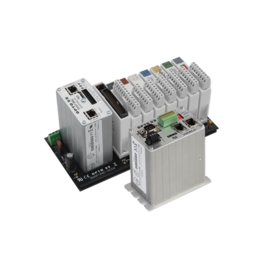

groov EPIC

For the IIoT - or any automation application

groov-EPIC world's first edge programmable industrial controller for the IIot (Industrial IoT).

Completely new system with real-time control, modular I/O level, local and remote HMI and industrial / IT data exchange in a compact, industrial package

OPTO22's new groov EPIC® system offers I/Os, control, data processing, visualization, data exchange and cloud connectivity for the IIoT (Industrial IoT) in a single system. Combining newly designed intelligent I/O with an integrated Linux® real-time controller, gateway functions and an integrated display, groov EPIC offers a field-proven industrial hardware design with modern, open software interfaces. Connect existing systems, control processes and automate machines, connect web services and create mesh networks, collect, publish and visualize data where it is needed (locally, remotely and in the cloud) - all in one system. The ability to easily share data and use it where it's needed opens up possibilities that automation engineers never had before. The groov EPIC system is of particular interest for process control, machine control, OEM, manufacturing, SCADA / RTU, buildings and facilities, and IIoT applications. Important for OEMs (original equipment manufacturers) is the optional access to the Linux operating system through Secure Shell (SSH). This access, along with toolchains and interpreters for Java, C / C ++, Python, JavaScript / Node.js and more, allows OEM developers to run their own custom-developed applications on this robust edge processing control system.

- Industrial, modular, intelligent I/O, real-time Linux-based automation control and edge gateway in a single system

- UL hazardous area approved and ATEX compliant

- Integrated high-resolution color touch screen with HDMI output for optional external monitor

- Compact footprint with integrated power supply and front design

- On-board system configuration, commissioning and troubleshooting; no PC required

- Remote configuration and troubleshooting from any web browser on any device

- Two independent Gigabit Ethernet network interfaces

- Two USB ports for serial communications, touch screen monitors, or WLAN adapters - Multiple power supply options, including AC, DC, and passthrough

- Wide operating temperature range from -20 to 70 ° C

- Touch-sensitive pad on I/O modules for configuration, commissioning, and testing

- Spring terminal strip directly on the E / A module, which can accommodate up to 14 AWG

- LED indicators for module status at a glance and for individual discrete channels

- E / A module density of up to 24 channels per module

- Analog inputs with multiple functions to support voltage, current and loop sources in one module

- Analog input resolution of 20 bits with 0.1% accuracy over span

- Channel-to-channel isolation available for most I/O modules

- Real-time open source Linux operating system running on a quad-core industrial ARM® processor

- 2 GB RAM, 6 GB user space on an industrial solid-state drive

- groov software for tool-free configuration, commissioning and troubleshooting on board and manage from anywhere on the network

- PAC Control flowchart-based control development environment with scripting and visual debugger

- groov visualization server to create and view HMIs, trends and events for any mobile device or web browser; Also viewable locally on the integrated touch screen

- Node-RED flow-based development environment and runtime for edge data handling, processing, and communication

- Ignition Edge® from Inductive Automation® with drivers for Allen-Bradley®, Siemens® and others

- MQTT / Sparkplug protocol for efficient industrial publish / subscribe communication

- 100% backward compatible to SNAP PAC systems and SNAP Ethernet I / O

- Available Secure Shell access, SDKs and cross-compilers for custom applications

OPTO22 is a manufacturer with over 30 years of market experience in the automation and control sector based in Temecula, USA.

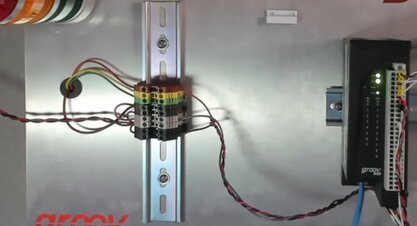

HY-LINE offers I/O switching modules and innovative Ethernet-based modular PAC/PLC control systems from the OPTO22 portfolio. With easy-to-learn programming language in flowchart technology, combined with high-level language, the systems are put into operation quickly, easily and effectively. The powerful HMI/SCADA visualization software is available license-free. Company-wide data exchange is realized via standard IT protocols. Solutions for data visualization on standard web browsers, including mobile versions, round off the complete system.

Since its creation in 1974, OPTO22 has become a household name for solid state relays all over the world. Through HY-LINE, OPTO22 offers a high-quality product range of solid state relays exclusively in Germany. OPTO22 solid state relays are also available as a complete set, with heat sink (also integrated), as a snap-in module for DIN rail mounting and in 1-2-3 phase versions.